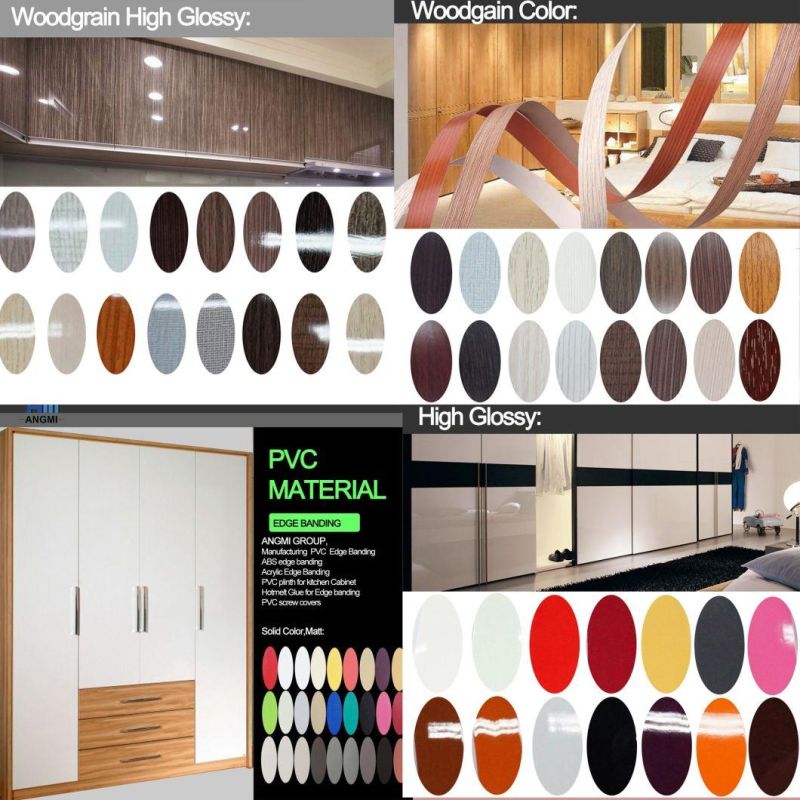

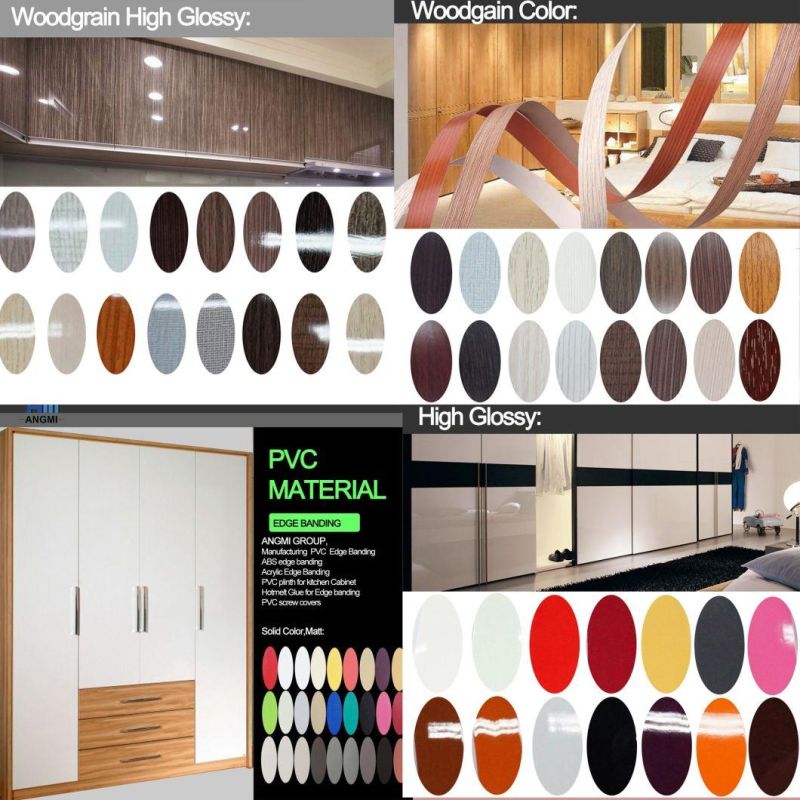

Solid Color/Wood Grain/ Embossed/ High Glossy/Matt High Tenacity PVC Edge Banding for Kitchen Cabinet

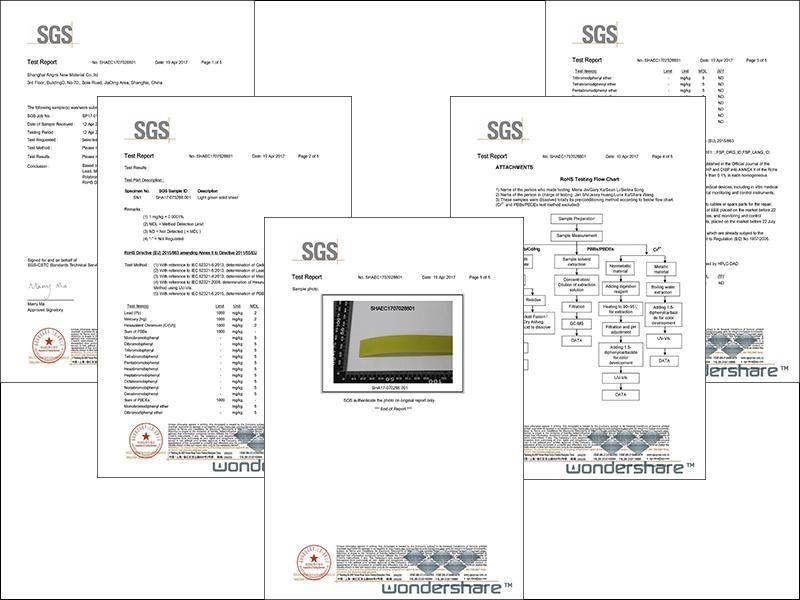

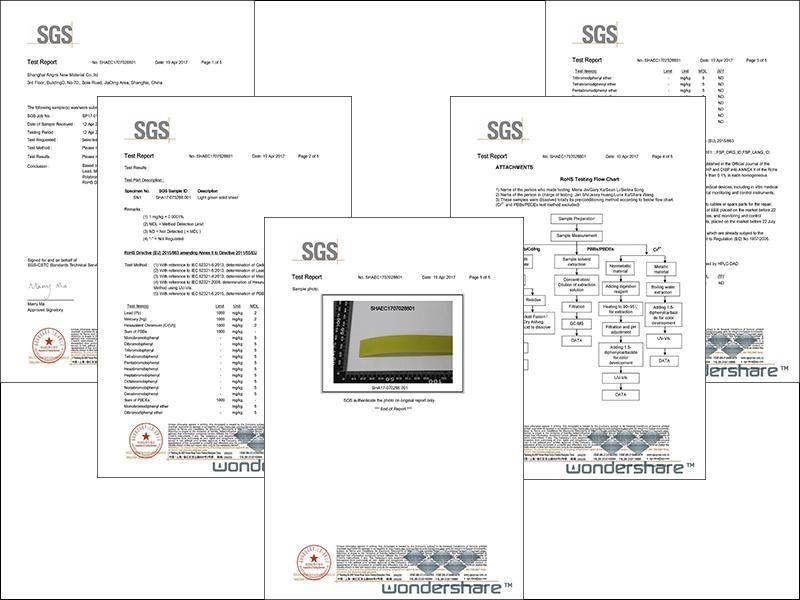

Shanghai Angmi New Material Co., Ltd.- Certification:SGS

- Material:PVC

Base Info

- Model NO.:PVC002A

- Usage:Cabinet, Door, Shelf, Table, chair, Sofa, Bed

- Condition:New

- Thickness:0.4-3mm

- Width:19-630mm

- Transport Package:Carton

- Specification:0.4mm--360mm*360mm

- Trademark:ANGMI

- Origin:China

- HS Code:3920490090

- Production Capacity:1000000meters

Description

FeaturesNon-color variation after trimming and polishing Strong bonding strength Superior durability and wearability Excellent light stability Stain and chemical resistance Heavy metal free Phthalates free No pressure whitening Packaging Protected with plastic foam and packaged in carton Supply ability 9000,000m per month MOQ 5000 Meters Shipping Date 15 days after receiving the advance payment or L/C Payment Terms TT or L/C at sight

Advantages

1. Keep the same hardness in winter and summer.

2. Fireproof, environmentally-Friendly, moisture-proof

3. Little color difference in each batch.

4. Never fade after more than 3 months' outdoor exposure to the strong sunlight.

5. With excellent back glue, and it won't fall from the furniture all the year round.

6. For wood grain, the texture is quite clear.

7. For high gloss, surface comparable to gloss / mirror finish

8. Smooth surface, high gloss, dumb gloss are optional.

9. Corrosion resistance, economical, stylish and durable, etc

10. High bending strength and easy to work

11. Widely used in furniture, office, kitchen utensils and appliances, teaching equipment, laboratory, etc.

Production process

1. Solid color PVC edge banding process:

Raw materials - mixing - granulation - extrusion - finished products.

2. Wood grain color PVC edge banding process:

Monochrome edge banding extrusion molding - roll coating base - gravure wood grain color -

-UV varnish - curing UV - finished products.

Application

How to distinguish the quality of PVC edge banding?

How to use PVC edge banding correctly ?

Package & Loading

Our Exhibition

Certificates

About Our Company

Founded in 2002,Shanghai Angmi New Material Technology Co.,ltd specialized in the R&D and production of PVC edge banding,PVC plinth,PVC screw cover caps and hot melt glue.Till now we've sold to more than 60 countries all over the world,such as Canada,Australia,Russia,Spain,UAE etc and get very good market feedback!

We started from producing high quality PVC edge banding, adpoted advanced technology and equipment from abroad and we have two production bases for PVC related products. We always pursuit in the high quality products,best customer service and win-win cooperation with the customers's all over the world!

Enterprise process

2002- Shanghai Angmi Founded,started to produce PVC edge banding for domestic market

2005-Established Export Department

2006-Started to produce PVC plinth for Kitchen/Cabinet

2007-Cooperated with the leading Kitchen/Cabinet manufacture in China market

2009-Enlarged our production line for ABS/Acrylic Edge banding

2010-The output Value exceeded the breakthough of 20million US dollars

2013 -Produced PVC screw cover caps

2018- Acquired the Hot Melt Glue Factory,started to produce and sell Hot Melt Glue

FAQ

Q: Are you a factory or trading company?

A: We are professional manufacturer, and we have more than 15 years for exporting and wood product's experiences.

Q: Where is your company located?

A: Our company is located in Shanghai City, China.

Q: Do you have MOQ request?

A: Our MOQ 5000 meters

Q: What is your delivery time?

A: The delivery time is 15-20days after received your deposit.

Q: What is the delivery port?

A: Shanghai Port

Q: Do the samples are available?

A: Yes, the sample is free and express charge on buyer account.

And after the order is confirmed, this charge could be returned from the order.

Q: May I visit your factory for inspection before placing the order.

A: You are warmly welcome to visit our factory anytime. Please let us know your

schedule in advance so that we can book hotel and arrange pickup for you.

Advantages

1. Keep the same hardness in winter and summer.

2. Fireproof, environmentally-Friendly, moisture-proof

3. Little color difference in each batch.

4. Never fade after more than 3 months' outdoor exposure to the strong sunlight.

5. With excellent back glue, and it won't fall from the furniture all the year round.

6. For wood grain, the texture is quite clear.

7. For high gloss, surface comparable to gloss / mirror finish

8. Smooth surface, high gloss, dumb gloss are optional.

9. Corrosion resistance, economical, stylish and durable, etc

10. High bending strength and easy to work

11. Widely used in furniture, office, kitchen utensils and appliances, teaching equipment, laboratory, etc.

Production process

1. Solid color PVC edge banding process:

Raw materials - mixing - granulation - extrusion - finished products.

2. Wood grain color PVC edge banding process:

Monochrome edge banding extrusion molding - roll coating base - gravure wood grain color -

-UV varnish - curing UV - finished products.

Application

How to distinguish the quality of PVC edge banding?

| PVC edge banding is divided into several proportions according to the ratio of added PVC and calcium carbonate. When the proportion of calcium carbonate is high, the physical properties are unstable, the PCV edge banding will be easily broken and fade color. High-quality PVC edge banding, due to the high proportion of PVC components, product stability is very high, then it will not be easily broken and fade color. The quality of PVC edge banding is generally reflected in the following aspects: 1. The surface is smooth, no bubbles, no lines, and the gloss is moderate; 2. The surface and back are flat, uniform in thickness and uniform in width; 3. The hardness is reasonable, the higher the elasticity, the better the quality and the stronger the wear resistance; 4. The back treatment agent is transparent or white, and The coating should be uniform. If it is not handled properly, it will result in low adhesion and even unable to be bonded after the edge banding; 5. The color of each batch of edge banding should be as consistent as possible. The smaller the color difference of different batches, the better the quality; 6. No debris and gaps while trimming and cutting. |

How to use PVC edge banding correctly ?

| 1. Mostly, the higher the temperature, the better the bond strength. It is recommended to use medium and high temperature hot melt adhesive as much as possible for best results. 2. Manual edge banding machine or semi-automatic edge banding machine are not recommended , because there is no polishing function, it is recommended to manually polish to ensure the trimming effect. 3. During the process of use, if the glue line is too thick or there is overflowing and drawing, it is necessary to adjust the speed of the edge banding machine and the temperature of the hot melt adhesive. 4. If the surface of the edge banding tape is easily scratched by the equipment during the edge sealing process, the surface of the edge banding tape is not properly treated and is unqualified. 5. In the process of using the edge banding, if the sealing does not occur, please check whether the indoor temperature and hot melt temperature are correct (no less than 18°C) or the speed of edge banding machine is too slow. |

Package & Loading

Our Exhibition

Certificates

About Our Company

Founded in 2002,Shanghai Angmi New Material Technology Co.,ltd specialized in the R&D and production of PVC edge banding,PVC plinth,PVC screw cover caps and hot melt glue.Till now we've sold to more than 60 countries all over the world,such as Canada,Australia,Russia,Spain,UAE etc and get very good market feedback!

We started from producing high quality PVC edge banding, adpoted advanced technology and equipment from abroad and we have two production bases for PVC related products. We always pursuit in the high quality products,best customer service and win-win cooperation with the customers's all over the world!

Enterprise process

2002- Shanghai Angmi Founded,started to produce PVC edge banding for domestic market

2005-Established Export Department

2006-Started to produce PVC plinth for Kitchen/Cabinet

2007-Cooperated with the leading Kitchen/Cabinet manufacture in China market

2009-Enlarged our production line for ABS/Acrylic Edge banding

2010-The output Value exceeded the breakthough of 20million US dollars

2013 -Produced PVC screw cover caps

2018- Acquired the Hot Melt Glue Factory,started to produce and sell Hot Melt Glue

FAQ

Q: Are you a factory or trading company?

A: We are professional manufacturer, and we have more than 15 years for exporting and wood product's experiences.

Q: Where is your company located?

A: Our company is located in Shanghai City, China.

Q: Do you have MOQ request?

A: Our MOQ 5000 meters

Q: What is your delivery time?

A: The delivery time is 15-20days after received your deposit.

Q: What is the delivery port?

A: Shanghai Port

Q: Do the samples are available?

A: Yes, the sample is free and express charge on buyer account.

And after the order is confirmed, this charge could be returned from the order.

Q: May I visit your factory for inspection before placing the order.

A: You are warmly welcome to visit our factory anytime. Please let us know your

schedule in advance so that we can book hotel and arrange pickup for you.